#What is cold formed steel framing full

The main objective of this research project is to study the application of structural systems based on light gauge cold-formed steel framing to housing in subsidence zones, having the following scopes: characterize the typical settlements in a discontinuity due to subsidence, to build a laboratory facility to simulate these settlements, to simulate and to evaluate numerically and in laboratory in a full scale model the structural performance of a house subjected to settlements due to subsidence, in terms of its stresses and strains and, eventually, its capacity of retrieval to its nondeformed shape. Correa 4ġ Universidad Autonoma de Aguascalientes, Department of Construction and Structures, Aguascalientes, MexicoĢ Universidad Autónoma de Chiapas, Engineering School, Chiapas, Mexicoģ Instituto Tecnologico Aguascalientes, Department Electric and Electronic Engineering, Aguascalientes, MexicoĤ Universidad Politecnica de Aguascalientes, Department of Mechanical Engineering, Aguascalientes, Mexico It also fosters project team collaboration, allowing other trade members to successfully complete their scope of work.J.-A. CFS framing is manufactured off-site with pre-punched holes to accommodate for mechanical, electrical and plumbing installation.

The Ironwood team efficiently manages ordering materials to maintain a productive construction schedule while minimizing on-site waste.Ĭold-formed steel framing’s manufacturing process allows for subcontracting teams to more simply integrate their work into the system. construction team has extensive experience in installing CFS framing in a variety of project sizes and types. How Ironwood Utilizes CFS on the Construction Jobsite And should any material be trimmed or cutaway, steel is 100% recyclable for reuse. Because installers are able to order CFS framing pieces cut and ready for installation, framing is done more quickly, with less waste. Another benefit to the CFS manufacturing process is a significant reduction in on-site waste. Of significant cost savings to projects is the fact that CFS is also resistant to termites and fire that can result in high operating costs and insurances.įurthermore, the manufacturing process of CFS framing assures a high level of consistency in the material improving overall project quality. Additionally, CFS’s physical properties also mean that it does not take on moisture that typically causes framing to warp or buckle. As the premier supplier of steel frame construction products, Eisen specializes in the design, manufacturing, and delivery of cold formed metal framing. The physical properties of steel make the material ideal for environments where a significant amount of strength and ductility is necessary, such as high wind areas or areas susceptible to earthquakes. Unlike other framing methods such as wood plank, CFS framing does not warp, will not absorb moisture, and is resistant to termites and fire. The Benefits of Cold-Formed Steel FramingĬFS is ideal for use in construction due to the durability of the material. These CFS elements can be manufactured at a variety of material thicknesses to meet a range of structural and non-structural applications. Heat is not used in the manufacturing process to form the elements, hence cold-formed steel. Screw strength for support fasteners is determined in accordance with: a.

CFS studs are made using a special process in which steel materials are rolled at or near room temperature into various shapes to create steel. Just because two studs are made of steel doesn’t necessarily mean that they feature the same type of steel. Metal Construction Association Primer on Diaphragm Design c. Cold-formed steel framing refers to the use of CFS studs to frame a building.

#What is cold formed steel framing manual

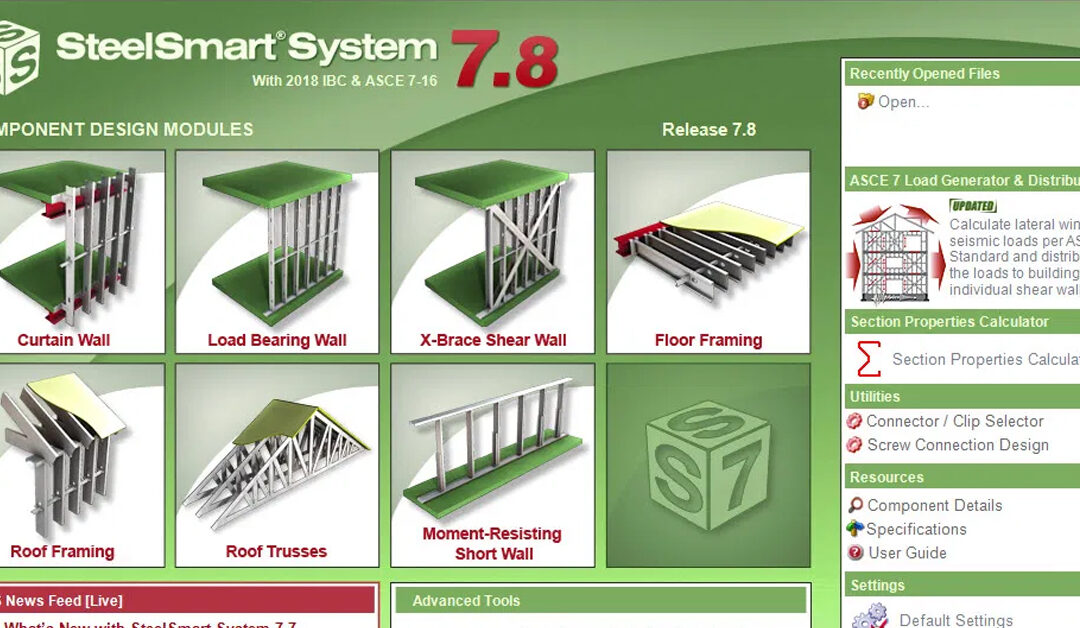

Steel Deck Institute Diaphragm Design Manual b. Basic steel diaphragm theory is found in. The ability to construct these members efficiently in mass quantity ultimately saves on schedule, waste, and budget.Ĭold-formed steel (CFS) components are metallic-coated steel sheets roll-formed into elements such as studs, joists, tracks, headers, and other components. Steel Roof Deck Diaphragms on Cold-Formed Steel Framing 1. Typically cold-formed steel (CFS) framing refers to non-load bearing partition walls and other vertical and horizontal structural elements that are formed by repeating CFS framing members. Cold-formed steel framing is a durable, non-combustible, lightweight framing option that is ideal for use in low to mid-rise commercial construction projects.

0 kommentar(er)

0 kommentar(er)